News

Structural features of electric butterfly valve

The electric butterfly valve has the advantages of simple structure, small volume, lightweight, less material consumption, small installation size. It is using for cutting, connecting and adjusting the medium in the pipeline, and has good fluid control characteristics and hermetically sealed. When the butterfly valve is in the fully open position, the thickness of the disc is the only resistance when the medium flows through the valve body, so the pressure fall-off generated by the valve is small. Therefore, its flow control is better.

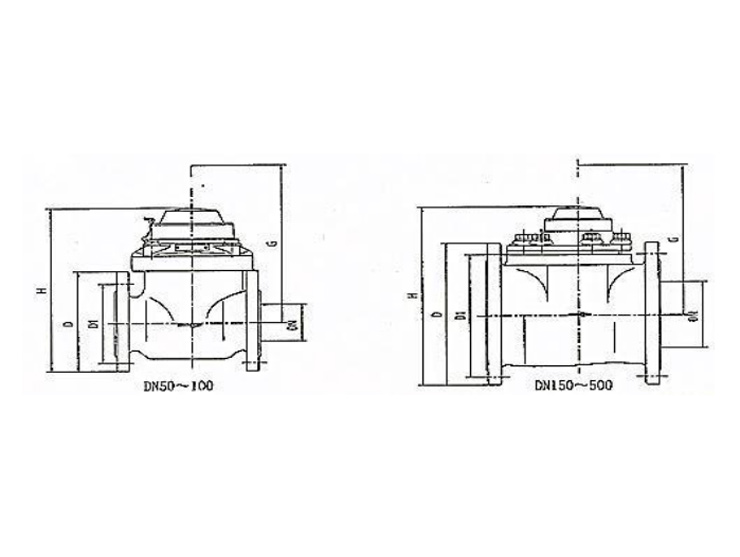

Electric butterfly valves has a variety type of electric valves and electric control valves. The connection methods mainly include flange type and wafer type. For example, the Shanghai VATTEN Valve Electric Butterfly Valve controls the butterfly valve switch through electric power. This product can use as a shut-off valve, control valve and check valve for piping systems. It can meet specific conditions in different operating conditions by manual control, electric or pneumatic drive.

Electric butterfly valve structure features:

First, it has a stable sealing performance under high temperature and high-pressure conditions. Its special sealing system ensures high sealing performance from ultra-low temperature to ultra-high temperature range.

Secondly, the three-dimensional eccentric sealing system combined with the optimized design of the valve lead to a small opening resistance. The sealing surface of the disc is a tapered shape that protrudes upward. When the valve open, the points on the circumferential surface of the disc are simultaneously separating from the seal ring, and solid matter does not easily generate on the sealing surface. The valve closing process is accomplishing by elastic compression of the seal ring.

Third, there is no phase jam between the butterfly plate and the seal ring.

Fourth, the sealing performance of the valve is not affected by temperature changes.

Fifth, the diameter of the stem sealed by graphite. In short, this ensured that the metal seal has zero leakage before, during and after the fire. Therefore, it is an essential type of valve of fire safety.

It’s used in the field of textile, power station, petrochemical, heating and cooling, pharmaceutical, shipbuilding, metallurgy, light industry, environmental protection, etc.