News

Structural classification of valves

1. Classified by function and purpose

(1) Cut-off categories: such as gate valves, globe valves, plug valves, ball valves, butterfly valves, needle valves, diaphragm valves, etc. A shut-off valve, also known as a closed-circuit valve, has open or close function in the pipe.

(2) Check valve: check valve is automatic valve, its function is to prevent the medium in the pipeline from flowing backward, prevent the pump and drive motor from reversing and the container the leak of the media.

(3) Safety categories: such as safety valves, explosion-proof valves, accident valves, etc.

(4) Adjustment level: such as regulating valve and pressure reducing valve, its function is to adjust the pressure, flow and other parameters of the medium.

(5) Special purpose categories: such as pigging valves, exhaust valves, drain valves, exhaust valves, filters, etc. The exhaust valve is an indispensable auxiliary component in the pipeline system and is widely used in water supply and drainage pipes such as boilers, air conditioners, oil and gas, etc. , It is usually installed at the highest or elbow to eliminate excess gas in the pipeline, improve road efficiency and reduce energy consumption.

2. Classified by nominal pressure

(1) Vacuum valve: refers to a valve whose working pressure is lower than the standard atmospheric pressure.

(2) Low pressure valve: refers to the valve with nominal pressure PN≤1.6Mpa.

(3) Medium pressure valve: refers to the valve with nominal pressure PN of 2.5Mpa, 4.0Mpa and 6.4Mpa.

(4) High pressure valve: refers to the valve with working pressure PN of 10.0Mpa to 80.0Mpa.

(5) Ultra high-pressure valve: refers to the valve with nominal pressure PN ≥ 100.0Mpa.

(6) Filter: refers to a valve with a nominal pressure PN of 1.0 MPa and 1.6 MPa.

3. Classified by working temperature

(1) Ultra-low temperature valve: medium operating temperature valve t < - 101 °C.

(2) Cryogenic valve: suitable for valves with medium working temperature -101 °C ≤ t ≤ -29 °C.

(3) Normal temperature valve: for valves with medium working temperature -29 °C <t <120 °C.

(4) Medium temperature valve: medium working temperature valve 120 °C ≤ t ≤ 425 ° C

(5) High temperature valve: a valve with a medium operating temperature t > 425 °C.

4. Classified by driving method

According to the driving method, it is divided into automatic valve type, power driven valve type and manual valve type:

(1) Automatic valve refers to a valve that does not require external force to drive, but relies on the energy of the medium itself to drive the valve. Such as safety valves, trap valve, check valves, automatic regulating valves, etc.

(2) Power valve: The power valve can be driven by various power sources. Divided into electric valve, hydraulic valve and so on.

Electric valve: with electric valve.

Pneumatic valve: A valve driven by compressed air.

Hydraulic valve: A valve that is driven by liquid pressure, such as oil.

In addition, there are combinations of the above several driving methods, such as a gas electric valve.

(3) Manual valve: The manual valve uses manpower to manipulate the valve through the hand wheel, handle, lever and sprocket. When the valve opening and closing torque is large, a gear or worm gear reducer can be provided between the hand wheel and the valve stem. If necessary, you can also use the universal joint and the drive shaft for remote operation.

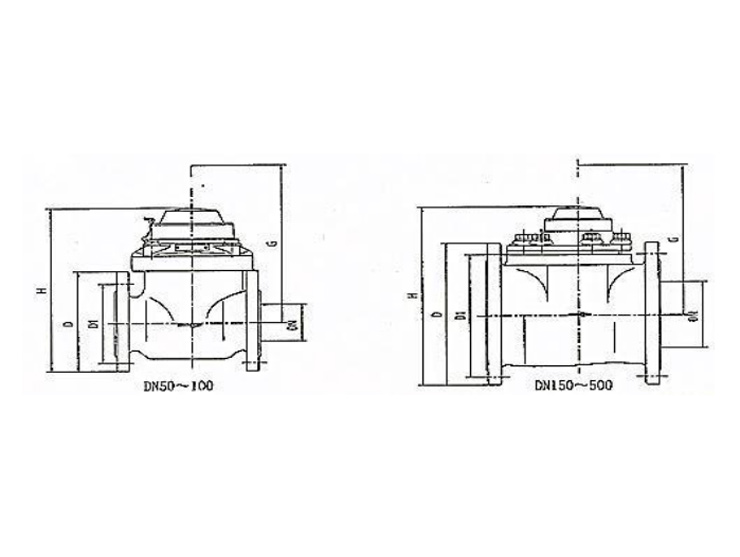

5. Classified by nominal diameter

(1) Small diameter valve: valve with nominal diameter DN ≤ 40mm.

(2) Medium diameter valve: A valve with a nominal diameter of DN of 50 to 300 mm.

(3) Large diameter valve: The valve of the nominal valve DN is 350-1200mm.

(4) Super large diameter valve: valve with nominal diameter DN ≥ 1400mm.

6. Classification by structural characteristics

The structural features of the valve are separated according to the direction in which the closure moves relative to the valve seat:

(1) Sectional shape: the closure moves along the center of the valve seat;

(2) Cock and ball: the closure is a plunger or ball that rotates around its centerline; such as a plug valve, ball valve

(3) Gate shape: the closure moves along the center of the vertical valve seat; such as gate valves, gates, etc.

(4) Swing shape: the closing member rotates around the shaft outside the valve seat; such as a swing check valve, etc.

(5) Butterfly shape: the disc of the closing piece rotates around the axis of the valve seat; such as butterfly valve, butterfly check valve, etc.

- Spool shape: The closing member slides in a direction perpendicular to the passage. Spool valve